American Barns in Australia: Tough Steel Sheds, Built Your Way

An American Barn is a high-clearance steel shed with a raised central bay and lower lean-to wings, designed to shelter vehicles, machinery, and mixed-use workshops while coping with Australian weather. This article explains what defines an American barn, how roof forms and materials affect performance, common uses across agricultural, commercial, and residential settings, customisation choices and clear guidance on cost drivers and quoting. Readers will learn how design choices influence functionality and longevity, why material selection matters for corrosion resistance, and practical steps to prepare for a quote. The content draws on regional building practice and material relationships—COLORBOND® and ZINCALUME®—to show how engineered steel sheds perform in the conditions of Melbourne and greater Victoria. Throughout the guide, we map design attributes to outcomes, compare common variants, and show how a local manufacturer with registered builder capabilities can support a project from design to handover.

What Exactly Are American Barn Sheds and Their Key Features?

An American Barn shed is a steel building type that combines a raised central gable or high bay with lower side wings to create a tall central clearance and sheltered lateral spaces, delivering flexible internal zoning and vehicle access. This geometry increases usable cubic volume for tall machinery, improves natural ventilation through ridge space, and provides protected lean-to areas ideal for workshops or storage. The practical benefit is a single footprint that supports mixed functions—vehicle storage in the centre and work or feed storage on the sides—while simplifying roofing and eave drainage. Understanding these core features helps owners choose the right variant for machinery, livestock, or commercial stock.

Key defining features of American Barns include:

-

- A raised central bay for maximum internal clearance and easy access for tall vehicles.

- Lean-to side wings that provide sheltered space for workshops or storage.

- Flexible internal layouts that can accommodate partitions.

- The use of top-quality steel cladding and engineered frames for lasting durability.

What Defines an American Barn Shed in Australia?

An American Barn in the Australian context is defined by its elevated central bay flanked by lower lateral wings, engineered as a steel-framed building to local structural requirements. This arrangement increases clearance, allowing tall vehicles and machinery to be housed beneath the central ridge while lean-to areas provide continuous covered workspace. The design is a hyponym of broader steel sheds and agricultural sheds, sharing common construction elements such as purlins, rafters, and cladding, but distinguished by its central high bay. Comparing this to conventional Australian barn forms shows the American Barn prioritises vertical volume and flexible internal zoning, useful for mixed-use rural and lifestyle properties.

This clear definition leads to consideration of how roof shapes and lean-to wings influence performance and layout.

How Do Gable Roofs and Lean-To Sides Boost American Barn Design?

Gable roofs increase central clearance and improve ridge airflow, which reduces heat buildup and helps shed water quickly, while lean-to sides create sheltered work zones that maintain simpler access. A gable central ridge delivers the maximum vertical space and balanced drainage; a mono-pitched option simplifies construction and can suit sites with shed orientation constraints. Lean-to wings act as meronyms of the overall building—components that convert the central volume into usable, segmented zones for storage, workshop, or stable functions. Choosing roof form impacts door placement, ventilation strategy, so roof selection should align with intended internal uses.

These roof and wing choices naturally lead into the materials used to ensure long-term durability in Australian conditions.

What Materials Are Used in Tru-Bilt American Barns?

Premium Australian steel is specified for panels and structure to resist corrosion and maintain appearance, with common options including COLORBOND® steel and ZINCALUME® steel, each offering distinct protective properties. COLORBOND® provides a painted finish with a wide palette that supports aesthetic blending into residential or rural properties, while ZINCALUME® delivers excellent corrosion resistance where a metallic finish is acceptable. Structural members are engineered to local standards to address wind and load demands, and coatings plus flashing detail reduce water ingress at junctions. These material choices support longevity and low maintenance when paired with appropriate drainage and design detailing.

Premium Australian steel is specified for panels and structure to resist corrosion and maintain appearance, with common options including COLORBOND® steel and ZINCALUME® steel, each offering distinct protective properties. COLORBOND® provides a painted finish with a wide palette that supports aesthetic blending into residential or rural properties, while ZINCALUME® delivers excellent corrosion resistance where a metallic finish is acceptable. Structural members are engineered to local standards to address wind and load demands, and coatings plus flashing detail reduce water ingress at junctions. These material choices support longevity and low maintenance when paired with appropriate drainage and design detailing.

How Can You Customise Your American Barn Design?

Customisation lets owners match an American Barn’s layout and fittings to specific needs such as vehicle storage, workshop functionality, or stable accommodation, balancing cost and capability. The mechanism of customisation relies on modular choices—roof form, door types, and cladding finishes—so decisions early in design determine structural requirements and price. The benefit of considered customisation is maximised usable space and tailored access, which improves day-to-day efficiency and asset protection. Below are the primary customisation categories and their effects on usability and engineering demands.

What Roof Styles and Layouts Are Available for American Barns?

Common roof styles are gable, mono-pitched, and open bay, each paired with layout variants such as single central lane, dual access bays, or integrated lean-to wings for side workshops. Gable roofs are the hyponym preferred for maximum clearance and balanced loads, while mono-pitched roofs reduce complexity and can suit sloped sites. Open-bay layouts prioritise unobstructed floor area for large equipment and simplify internal circulation. Choosing a roof and layout directly affects purlin spacing, ridge ventilation requirements, so early planning ensures the design meets both functional and engineering needs.

These layout choices lead directly to decisions about doors and windows suitable for different barn uses.

Which Door and Window Options Suit Different Barn Uses?

Door and window choices should match operational needs: roller doors for fast vehicle access, sliding doors for wide but shallow openings, and personal access doors for secure workshop entry, with windows and louvres providing light and ventilation. Roller doors are ideal for vehicle shelters and servicing bays because they permit full-width openings without impeding internal floor space. Sliding doors offer an economical option for equipment storage, and personal access doors provide secure, code-compliant access for staff. Windows and ventilation features support animal welfare in stable uses and worker comfort in workshops; consider security grilles and insect screens where appropriate.

These access and fenestration choices also influence the decision to add internal partitions.

How Do Internal Partitions Add Value?

Internal partitions allow dedicated spaces such as tack rooms, offices, storerooms, or wash bays, improving organisation and safety while maintaining the flexibility to reconfigure. The benefit is maximised utilisation of vertical volume in American Barns, transforming a high central bay into multi-level functionality.

Planning partitions early ensures load-bearing and access considerations are integrated into the shed’s structural design.

What Are the Common Uses for American Barns in Australia?

American Barns are versatile steel sheds that serve agricultural, commercial, and residential roles, offering a rectangular volume and high central clearance suitable for many applications. The mechanism behind their versatility is the separation of vertical and lateral zones—tall central bays for vehicles and machinery with lean-to sides for workshops, storage, and stables—enabling mixed-use occupancy. Owners gain flexible, durable space that can adapt over time as needs change, from seasonal storage to long-term workshop operations. Below are typical uses that show how configuration choices map to specific needs.

Common applications include:

-

- Agricultural storage: machinery, hay and feed, with separate lean-to feed rooms.

- Horse stables and equine facilities: tack rooms, ventilation, and partitioned stalls.

- Commercial workshops and light industrial uses: servicing bays, fabrication and parts storage.

These use cases lead to specific design recommendations for ventilation, drainage, and access which inform cost drivers and quoting processes.

How Are American Barns Used for Agricultural Storage and Horse Stables?

For agricultural storage, American Barns provide tall clearances for tractors and hay stacking with side wings used for feed, tools, and grain bins; partitioning protects stored items and improves organisation. In equine applications, partitions create individual stalls, and ventilation strategies—ridge vents, louvres, and raised eaves—support animal welfare by reducing heat and moisture. Designers should incorporate non-slip flooring, appropriate drainage, and secure storage for feed and equipment to reduce risks. These adaptations demonstrate how a single American Barn footprint can meet both machinery protection and livestock care requirements effectively.

These agricultural and stable uses share design needs with commercial workshop applications, which we describe next.

What Commercial and Workshop Applications Suit American Barns?

American Barns suit light industrial and workshop uses where high bays accommodate service lifts, tall racking, or large fabrication equipment; lean-to wings become assembly or storage zones. Practical layout considerations include durable concrete flooring, electrical reticulation for machinery, and lighting and extraction where welding or fabrication occurs. Security choices—high-set roller doors, lockable personal doors, and minimal unobstructed glazing—protect tools and stock. These setups benefit businesses requiring a balance between secure storage and active workspaces.

The residential and lifestyle uses of American Barns often prioritise aesthetics and council compliance alongside functional layout.

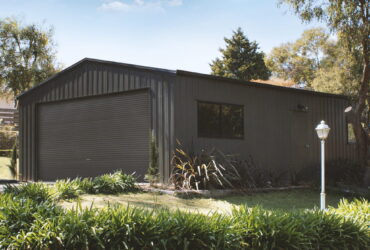

How Do American Barns Serve Residential and Lifestyle Needs?

In residential contexts, American Barns convert to large garages, hobby workshops, studios, or combined garage-plus-studio spaces where colour and cladding choices are important for visual integration. COLORBOND® colour options allow owners to match existing homes or rural landscapes, while internal partitions can create hobby rooms, additional storage, or minor secondary living areas where permitted. Planning and local council considerations, including setbacks and building classification, influence feasible sizes and uses. Thoughtful finishes and layout choices allow an American Barn to support lifestyle goals without compromising durability.

These examples of use make it easier to assess why choosing a local supplier with comprehensive services is valuable.

Why Choose Tru-Bilt American Barns for Your Melbourne or Victoria Property?

When it comes to selecting the perfect barn for your property, Tru-Bilt’s American Barns stand out as a top choice. With a commitment to quality craftsmanship and exceptional design, Tru-Bilt combines traditional aesthetics with modern functionality. Whether you’re looking to establish a functional workshop, create additional storage space, or even host community events, Tru-Bilt American Barns offer versatile solutions tailored to meet your specific needs.

If you would like to know more about specific costs and inclusions, simply request a quote on our website and our team will be in contact with you to discuss your needs.