Ideal Hay Shed Solutions – Steel Sheds Melbourne

Custom Steel Hay Sheds in Victoria: Durable Storage Solutions for Farmers

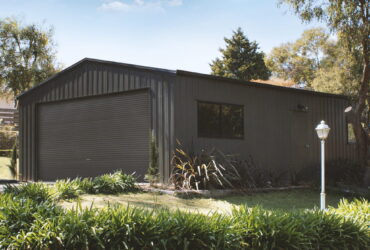

Ensuring hay remains dry, accessible and protected underpins farm efficiency and animal health. Custom steel hay sheds deliver engineered durability, weather resistance and design flexibility that boost storage capacity and reduce spoilage. This guide outlines the key shed types, design and customisation strategies, planning and permit requirements, material advantages, and investment considerations you need to optimise hay storage in Victoria. Tru-Bilt Fabrications is part of A-Line Building Systems, who can manufacture and install custom steel hay sheds across Melbourne and regional Victoria, supporting farmers with end-to-end solutions.

What Are the Different Types of Hay Sheds Available in Victoria?

Open-front, enclosed and distinct roof-style hay sheds each serve specific storage needs and site conditions. Understanding these options helps farmers select the ideal shed for hay protection, ease of access and climate resilience.

What Are the Features of Open Front Hay Sheds?

Open front hay sheds feature an unobstructed façade that streamlines loading and promotes natural ventilation for moisture control.

- Steel portal-frame construction ensures structural strength.

- Wide bay openings accommodate large bales and machinery.

- Overhanging roof reduces weather ingress while maintaining airflow.

Open fronts excel where rapid access and cost-effective construction are priorities, setting the stage for discussing fully enclosed alternatives.

How Do Enclosed Hay Sheds Provide Maximum Protection?

Enclosed hay sheds integrate side and rear cladding to shield hay from wind-driven rain, dust and vermin intrusion.

- Colorbond steel walls deliver corrosion resistance and fire-rated protection.

- Roller or sliding doors secure the internal environment.

- Insulated roof panels can further stabilise internal temperatures.

By sealing out external elements, enclosed structures maximise hay longevity before we examine roof-style variations.

What Are the Benefits of Gable and Skillion Roof Hay Sheds?

Gable and skillion roofs influence water runoff, internal clearance and construction cost.

Gable roofs improve drainage and create a lofted centre, while skillion designs simplify construction and reduce material use, guiding us toward custom dimensions and layouts.

How Can You Design and Customise a Hay Shed for Optimal Storage?

Custom design aligns shed geometry, internal workflow and environmental controls to farm operations. Careful planning of dimensions, ventilation and specialised features maximises hay quality and handling efficiency.

What Are the Ideal Dimensions and Layouts for Hay Sheds?

Optimal hay shed size balances storage capacity with equipment access and manoeuvring space.

- Bay spacing of 6–9 m suits standard round or square bales.

- Eave heights of 4–6 m accommodate high-stacked storage.

- Clear span widths reduce internal obstructions.

Design layouts that position entry bays near loading zones and segregate dry hay from work areas before considering airflow strategies.

How Does Ventilation Improve Hay Storage in Steel Sheds?

Ventilation systems remove moisture and heat, preventing mould and spontaneous combustion.

- Ridge-vent capping allows warm air to escape at roof apex.

- Louvre or whirlybird vents at eaves draw in cool air.

- Roof insulation minimises temperature fluctuations.

Hay Storage and Spoilage Reduction

Proper ventilation in hay sheds is crucial for reducing moisture and preventing spoilage, which can lead to significant economic losses for farmers. Effective airflow helps to maintain hay quality by minimising the risk of mould and spontaneous combustion, thereby extending its usable lifespan.

Effective airflow preserves hay quality, leading into ways to add custom features that enhance functionality.

What Custom Features Can Enhance Farm Hay Sheds?

Custom options tailor sheds to specific storage and operational needs.

- Integrated mezzanine platforms for small-bale storage.

- Automated climate-monitoring sensors to track humidity.

- Internal partitions for feed staging and equipment bays.

These enhancements support workflow and protect hay investment, setting up the need to meet planning and permit rules.

What Are the Planning and Permit Requirements for Hay Sheds in Victoria?

Regulatory compliance ensures safety, structural integrity and legal approval for farm buildings. Knowing when and how to obtain permits prevents project delays and fines.

When Is a Building Permit Required for Hay Shed Construction?

A building permit is required for sheds exceeding prescribed size thresholds or when electrical and plumbing fittings are included.

- Sheds over 100 m² typically need a permit.

- Ancillary fittings such as lighting or water lines trigger approvals.

Understanding these triggers ensures timely permit applications before site preparation.

At Tru-Bilt / A-Line, we are Registered Building Practitioners, so contact us for more in-depth details regarding your hay shed construction.

How Do Victorian Council Regulations Affect Hay Shed Projects?

Local councils enforce wind-rating, setback and heritage overlay controls that shape shed design and placement.

- Wind classification zones dictate steel section sizing.

- Boundary setbacks protect adjoining properties.

- Heritage overlays may require façade treatments.

Navigating local codes secures approval, leading into essential groundwork considerations.

What Site Preparation Is Needed Before Building a Hay Shed?

Site preparation establishes a stable foundation and drainage to protect the structure and stored hay.

- Level and compact subgrade to engineering specifications.

- Install gravel or concrete slab foundations per Australian Standards AS 2870.

- Grade surrounding soil to divert water away from the shed.

Proper groundwork underpins long-term performance, transitioning us to material choices.

Why Choose Steel Construction for Hay Sheds in Melbourne and Victoria?

Steel delivers superior strength, durability and design adaptability compared with timber or masonry alternatives. Farm sheds built from steel frames and Colorbond cladding resist extreme weather and require minimal upkeep.

What Are the Advantages of Steel Frames and Colorbond Cladding?

Steel portal frames and Colorbond panels offer:

- Industry-leading durability through use of 100% Australian steel.

- High tensile strength to span clear bays without internal posts.

- Corrosion-resistant coatings for long service life.

- Fire-rating benefits that can reduce insurance costs.

Steel Building Advantages

Steel construction offers superior strength, durability, and design flexibility compared to timber or masonry. Steel frames and Colorbond cladding are resistant to extreme weather conditions and require minimal maintenance, making them a cost-effective and long-lasting solution for hay storage.

Australian Steel Institute, Steel in Building (2022)

This citation reinforces the article’s claims about the benefits of steel construction for hay sheds, highlighting its advantages in terms of durability and weather resistance.

These material benefits improve shed resilience, introducing the role of foundations and installation quality.

How Are Foundations and Installation Handled by Tru-Bilt / A-Line?

Tru-Bilt’s turnkey process covers site survey, engineering design, fabrication and on-site assembly.

- Structural drawings comply with wind and seismic regulations.

- Pre-engineered components bolt together for rapid erection.

- Accredited installers ensure accurate alignment and sealing.

A seamless installation experience accelerates project timelines and delivers reliable performance ahead of cost considerations.

How Much Does a Custom Hay Shed Cost and What Are the Investment Benefits?

Custom hay shed pricing reflects size, design complexity and material specifications, while long-term value derives from durability, reduced spoilage and operational efficiency.

What Factors Influence Hay Shed Pricing in Victoria?

Hay shed cost drivers include:

- Shed footprint (length × width × height).

- Cladding grade and insulation options.

- Engineering complexity for special features.

Transparent cost breakdowns help farmers budget effectively, guiding financing and ROI analysis.

At Tru-Bilt, you can request a free Hay Shed Quote so that you know the exact costs associated with your build.

What Is the Return on Investment for Durable Steel Hay Sheds?

Steel hay sheds pay dividends through reduced hay spoilage, lower maintenance costs and improved operational uptime.

- Proper ventilation can cut spoilage losses by up to 30%.

- Fire-resistant cladding may reduce insurance premiums.

- Modular expansion capability accommodates farm growth.

Over a 15-year lifespan, these factors combine to deliver strong ROI and sustainable farm productivity.

Conclusion

Investing in custom steel hay sheds provides farmers with durable, weather-resistant storage solutions that enhance hay quality and reduce spoilage. By understanding the various types, features, and planning requirements, you can make informed decisions that align with your operational needs.

Explore our range of Hay Sheds to optimise your hay storage and ensure long-term efficiency. Or, contact Tru-Bilt Fabrications today to discuss your specific requirements and get started on your custom solution.